Tube Manufacturing

Key is a full service tube component supplier; from drawing tube to brass fittings to bending and final assembly, Key has it all in house.

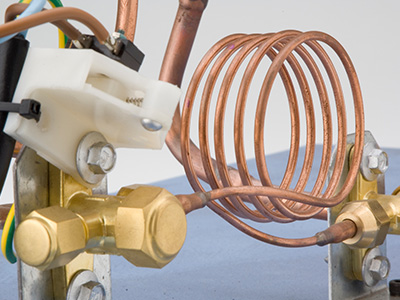

Brazing, Soldering and Welding

Key specialises in all forms of brazing and TIG welding, manufacturing with basic components through to full manufactured assemblies. Final manufactured assemblies are comprehensively cleaned via our ultrasonic cleaning station. This removes any residue fluxes and carbons from the brazing process. Leak testing is performed as a final Key assurance of total quality.

Design and Assembly

Tubing from concept and design to manufacturing the final product: Whether you are a high volume supplier or deal in short runs with low volumes, Key has the knowledge, customisation skill and manufacturing equipment to deliver custom and bulk tube on time, on budget and all built to exacting standards.

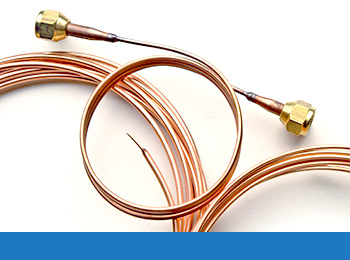

End Forming

Key can provide customised end forming manufacturing solutions such as flaring, expanding, and deburring plus a full range of end spun accumulators in a range of materials and sizes.

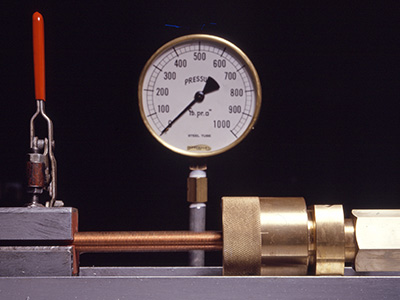

Quality and Testing

We pride ourselves on our quality assurance procedures and advanced testing equipment to ensure our customers receive the same product standards over and over again.

Cut to Length

Manufactured tubing can be supplied in coil form or cut to length, to our customers’ requirements, through our Burr Oak straight tube cut off line which uses the cutting technology of groove and pull providing a swarf and oil free end finish. All products supplied in coil and cut to length are eddy current tested for any defect to ensure a quality product. This process allows us to customise our manufactured coils to suit your requirements.

Coiling and Bending

Our CNC 3-axis bending equipment converts your drawing into repeatable production of tubular manufactured components. To complement our CNC bending equipment we use a metrology level CMM tube measuring system to guarantee accuracy, every time. This system also supplies an X, Y & Z customer off tool sample report. We specialise in most forms of tube bending such as Copper, aluminium, brass, stainless steel, Bundy tube and mild steel; giving you the customisation power and comfort in our manufacturing capabilities.

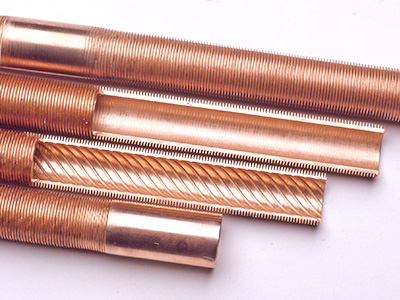

Copper & Copper/Nickel Finned Tubing

We are Australia’s largest manufacturer and producer of copper and copper / nickel low finned tube, used widely in the mining, air conditioning and refrigeration industries. Our in-house finning process provides excellent heat exchange properties for these vital industries.

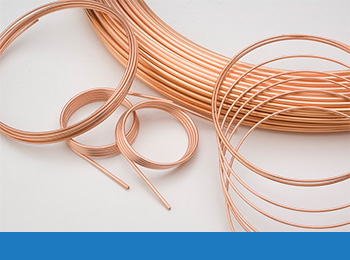

Custom Coil and Bulk Coil

Key provide an extensive range of coil in most metals, and can manufacture custom coil in all manner of sizes and diameters. We also supply bulk coil lengths, and off the shelf coil standard packs in common sizes are also available.

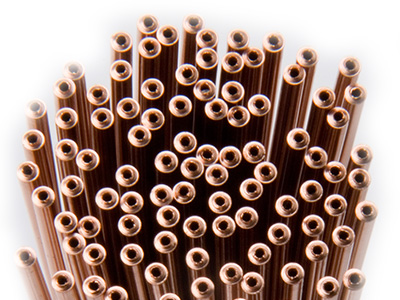

Tube Drawing

Key manufactures precision drawn copper and aluminium tubing with tight dimensional tolerances and a high standard of cleanliness as required by our many customers. This can be supplied in hard drawn or annealed through our own copper annealing ovens. In addition Key can produce most combination of outside/inside dimensions to meet our customers’ custom requirements.